Loudspeaker amplifier, also known as PA amplifier, plays an important role in providing clear and powerful sound in various situations such as concerts, conferences and meetings. This audio amplifier is designed to amplify the audio signal from microphones and other sound sources and transmit it to a large audience.

At next sections we will discuss the problems encountered in mass production, and the steps taken to ensure first-class quality.

Problems in mass production of power amplifiers

When mass producing power amplifiers, there are several problems that must be solved to ensure high quality. One of the main challenges is maintaining consistency throughout the manufacturing process. In high-volume production, it is very important to ensure that all amplifiers meet the required specifications and standards.

Another challenge is managing production schedules and meeting demand. Mass production requires efficient planning, coordination and allocation of resources to ensure on-time delivery. Delays in the production process can lead to customer dissatisfaction and lost business opportunities.

In addition, cost optimization is a key issue in mass production. A balance must be struck between producing high quality loudspeaker amplifier and keeping production costs within budget. Reducing the cost of quality can lead to poor performance and customer dissatisfaction. Therefore, it is very important to implement cost-effective measures without compromising the quality of loudspeaker amplifiers.

Steps to ensure high quality in mass production

To ensure high quality in mass production of loudspeaker amplifiers, we take a systematic approach and adhere to ISO 9001:2015 standardized processes. The key steps are as follows:

Engineering and design

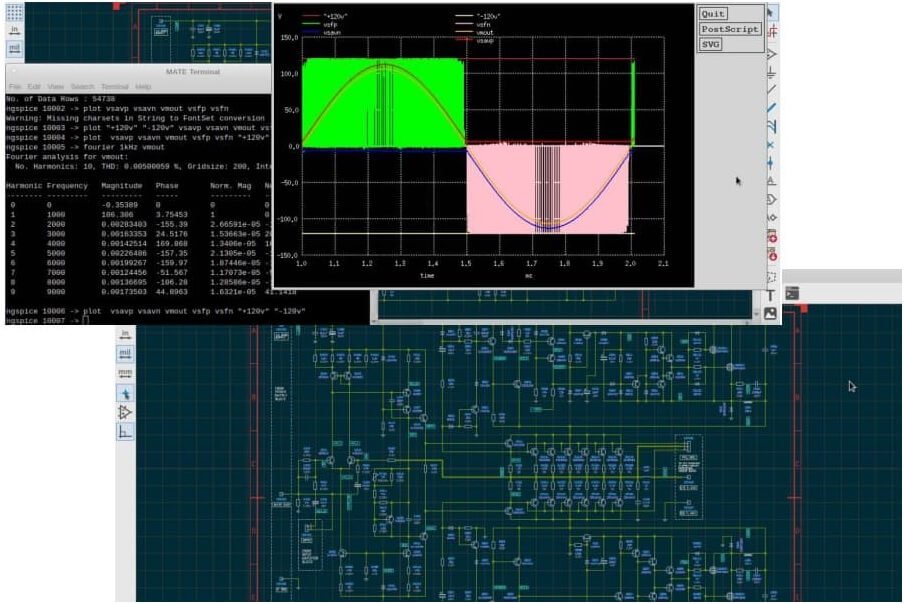

The first step is to develop a robust design and construction plan. This involves thorough research, prototyping and testing to ensure that the PA amplifier meets your requirements. It is essential that experienced engineers and designers who understand the complexities of audio amplifiers are involved.

We have a team of experienced design engineers who have been in these positions for over a decade. This is an important resource that we have as a specialized manufacturer in the audio sector.

Selecting suitable raw material suppliers

We carefully evaluate potential suppliers. This includes their track record, quality control measures and ability to meet our production requirements. Regular audits and inspections of suppliers help to ensure the required quality standards. In addition, we maintain long-term and stable relationships with reputable suppliers of branded components.

Quality control measures

Strict quality control is necessary to detect deviations from the required quality standards.

This includes regular inspections, sample testing and performance evaluation throughout the production process.

Inspection at receipt of raw materials, inspection during production and inspection of finished products are processes that must be carried out for each order. Defective products are identified and corrected before they reach the finished goods warehouse.

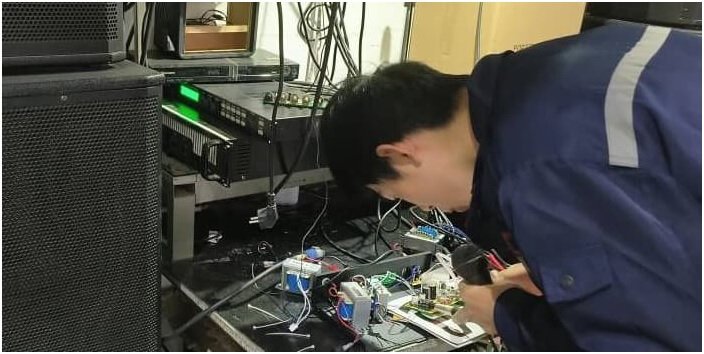

Employee training

Providing comprehensive training to production staff is an important process. The company conducts regular training programs for new employees. This helps to improve their skills and productivity and minimize errors in the production process.

Continuous improvement of production processes

Continuous improvement plays an important role in maintaining quality in mass production. We regularly analyze our manufacturing processes to identify areas for improvement and implement corrective measures. This will improve efficiency, reduce waste and optimize overall production quality.

Testing and quality control of loudspeaker amplifier

Let’s return to the most important step in ensuring consistent quality: testing and quality control.

To guarantee the quality of loudspeaker amplifiers in mass production, rigorous testing and quality control measures must be implemented. The following are some important aspects to consider:

Component testing

Every component used in the loudspeaker amplifier must be tested for operability, performance, and durability. This includes testing integrated circuits, transistors, capacitors, resistors, and other electronic components. We have specialized equipment to perform a range of tests to ensure accurate results.

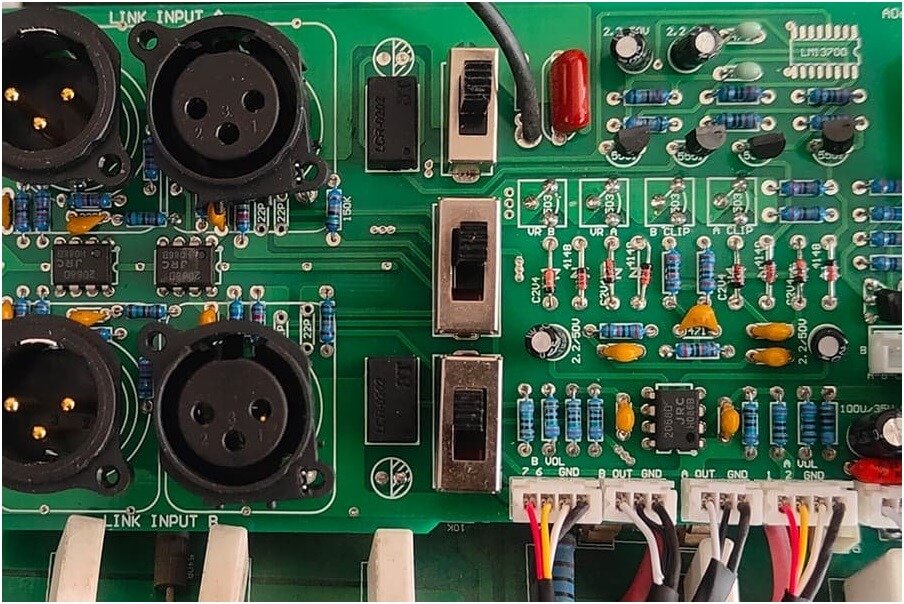

Printed circuit board testing

Printed circuit boards must be thoroughly tested to ensure that there are no defects such as short circuits, broken wires and poor connections. We have professional automatic PCB testing equipment (also known as OK machines) to quickly identify defects.

Sound performance testing

The sound performance of all power amplifiers is tested to ensure that they meet expected specifications. This includes testing parameters such as frequency response, total harmonic distortion, signal-to-noise ratio and power output.

Durability and aging tests

Loudspeaker amplifier is exposed to a wide range of environmental conditions and usage scenarios. Therefore, durability testing is critical to ensure that amplifiers can withstand the rigors of real-world applications. This includes testing for extremes of temperature, humidity, vibration and mechanical stress. All speaker amplifiers require aging tests to ensure that they can operate under constant high and low voltage shocks.

Final quality check

A final quality check is performed before the pro power amplifiers are shipped to the customer. It includes visual inspection, functional testing and performance evaluation. Any discrepancies are corrected before the amplifiers are packaged and shipped.

Through comprehensive testing and quality control measures, we can ensure that all PA amps produced during mass production meet customer requirements.

Conclusions and key points

A standardized approach is necessary for mass production of high-quality loudspeaker amplifier. At the same time, thorough testing and continuous process optimization are necessary.

Comprehensive testing and quality control measures are important to detect any deviations. In addition, all quality checks must be completed before the product reaches the finished goods warehouse.